In the previous section we saw the arrangements of top bars at various types of supports. In this section we will see the top bars at simple supports.

When the beam or slab is simply supported, the bending moment at the support is equal to zero. So theoretically there is no need to provide top steel at the supports. A similar situation arises in continuous beams and slabs also, when the end span is simply supported at the discontinuous end. But the code requires us to provide top steel in these cases also. This is because, if a partial fixity is induced at the support, there will be a negative (hogging) moment. A presentation showing an example of partial fixity is shown here. In such cases top steel will be required to resist the hogging moment.

First we will see the details of the simply supported end of a slab. We have to follow the clause D -1.6 of the code in this case. This clause gives us the requirements regarding the two parameters: (i) quantity and (ii) length.

(i) Quantity: The area to be provided for the top bars is equal to half of the area of bottom steel required at the midspan.

(ii) Length: The length of each top bar should be equal to 0.1l . Where l is the effective span.

The above requirements can be satisfied by providing bars as shown in the following figs.

Fig.15.57

Top bars at the simple supports of a slab

Now we will see the simply supported end of a beam. For this we have to follow cl.22.5.2 of the code. This clause gives us the procedure to determine the amount of steel that has to be provided:

Where W is the total factored load on the span, and l the effective span.

• Then we determine the amount of steel required to resist this moment. This much steel has to be provided as top steel at the simple support of the beam. This is the 'quantity'.

Now we need the length for which this much steel is to be provided. We know that for a beam, there will always be two bars acting as ‘stirrup hangers’ at the top. We must provide these two bars in such a way that their total area will be greater than that required to resist the moment in 15.8. So the ‘area requirement’ will be satisfied. We also know that these bars being 'stirrup hangers', will extend from support to support. That is., they are provided for the full length of the beam. So the ‘length requirement’ if any, will also be satisfied. But we have to provide enough embedment [Ld (unique value)] for these two bars into the support. These details are shown in the fig.15.58 below:

Top bars at the simple supports of a Beam

The above fig.15.58 can be used for a single span simply supported beam, and also for the discontinuous end of a multi-span continuous beam. If this discontinuous end is simply supported.

So we have completed the discussion about top bars. That is., bars provided to resist the hogging moment. These bars are provided at the supports.

We have seen the method of curtailment of Top bars at various types of supports. It will be better to compile the discussions that we had about this topic in a compact form. The fig.15.59 below shows the five types of supports at which we discussed the top bars.

We have seen the method of curtailment of Top bars at various types of supports. It will be better to compile the discussions that we had about this topic in a compact form. The fig.15.59 below shows the five types of supports at which we discussed the top bars.

Support conditions

The descriptions about each of the above supports and the links to the figs., explaining the curtailment of top bars at that support are given below:

(i) Support of a single span simply supported member [Figs.15.57 and 15.58 shown above]

(ii) End support (which is simply supported) of a multi span continuous member [Figs.15.57 and 15.58 shown above]

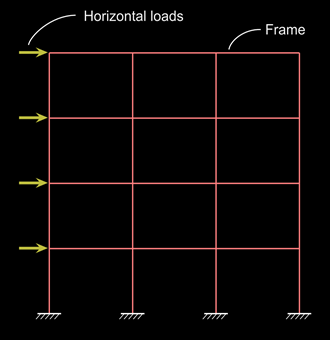

(v) Intermediate support of a continuous beam which is part of a frame. [Figs.15.53 and 15.54]

Just as we did the final check for development length in the case of bottom bars using fig.15.50, we have to do the final check for top bars also. Here we will consider each of the above five cases separately.

Just as we did the final check for development length in the case of bottom bars using fig.15.50, we have to do the final check for top bars also. Here we will consider each of the above five cases separately.

(i) For this case, the Ld requirement to prevent the bar from pulling out from the support, is shown in the fig.15.58 itself.

(ii) For this case also fig.15.58 can be used.

(iii) For this case, the Ld requirement to prevent the bar from pulling out from the support, is shown in the Figs.15.55 and 15.56 itself.

In general, the above three cases are end supports, and so it is easy to give the required Ld at the design stage itself.

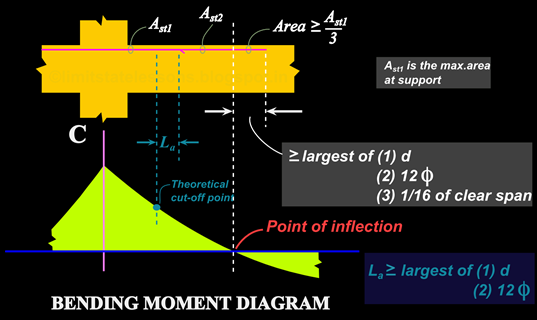

(iv) For this case, Ld requirement is shown in the fig.15.60 below:

Development length requirements for top bars of continuous beams

The details shown in the above fig. can be explained as follows:

At the support, the beam will be bending upwards due to the hogging moment. So the bars will be in tension, and they will try to 'contract' which is same as 'pulling into' the support. So all the bars should have a minimum Ld from the face of the support, and this length should be embedded into the span. This will prevent the bars from pulling into the support.

Similarly, at the cut-off section XX, the remaining bars will be under a greater tension. So each of these remaining bars should also be given the required Ld into the span.

Similarly, at the cut-off section XX, the remaining bars will be under a greater tension. So each of these remaining bars should also be given the required Ld into the span.

(v) For this case, Ld requirement can be shown just by modifying the support conditions of the previous case (iv). This is shown in the fig.15.61 below. The explanations are also the same.

Fig.15.61

Development length requirements for top bars of continuous beams in a frame

This completes the compilation for Top bars. Next we will make a similar compilation for Bottom bars:

For bottom bars also, the supports encountered are those shown in the fig.15.59 above. So we will discuss the five cases shown in that fig.

The descriptions about each of the supports and the links to the figs., explaining the curtailment of bottom bars at that support are given below:

(ii) End support (which is simply supported) of a multi span continuous member. [Same as above. Figs.15.42, 43 and 44]

(v) Intermediate support of a continuous beam which is part of a frame. [Figs.15.47]

We have to do a final check for development length in the case of bottom bars using fig.15.50. This completes the compilation for Bottom bars. In addition to the above, the application of 15.4 and 15.6 should be considered where ever necessary for both Top and Bottom bars. The largest length obtained should be provided in the final design.

In the next section we will discuss about 'Bent-up bars'.

We have to do a final check for development length in the case of bottom bars using fig.15.50. This completes the compilation for Bottom bars. In addition to the above, the application of 15.4 and 15.6 should be considered where ever necessary for both Top and Bottom bars. The largest length obtained should be provided in the final design.

In the next section we will discuss about 'Bent-up bars'.

Copyright©2016 limitstatelessons.blogspot.com - All Rights Reserved